DIFFICULTY LEVEL: Easy

APPLICABLE MODELS:

5 Series (1988-1995)

TOOLS NEEDED:

| floor jack | ||

| jack pad liners | ||

| jack stand | ||

| screwdriver (flat-blade) | ||

| wheel nut wrench (17 mm) | ||

| tire lever (or similar) | ||

| brush (small steel/brass) | ||

| ratchet wrench | ||

| breaker bar (long) | ||

| torque wrench | ||

| brake pad spreader | ||

| socket (5 mm Allen key) | ||

| socket (7 mm Allen key) | ||

| socket (long) (19 mm) | ||

| brake cleaner (CRC Bräkleen or similar) | ||

| anti-seize compound (Loctite 8009 or similar) |

PARTS REQUIRED:

front brake pads (1 set), brake pad wear sensor (one per axle)

2 Disc Brakes for Front

HOT TIP:

Wear gloves, brake dust and brake cleaner can harm you.

PERFORMANCE GAIN:

Proper brake function.

COMPLEMENTARY MODIFICATION:

Flush brake fluid. Replace brake rotors.

Failure Symptoms:

Brake lining message or light.

Grinding when coming to a stop.

Walkthrough

Removing Wheel

The first step will be to remove the wheel at the location where you want to replace brake pads. This includes raising the car and later on also working beneath the car. Therefore a couple of rules are listed that must be followed:

- Jacks are used only to get your car off the ground (they should never be used to hold a car in place)

- Always use jack stands when you work underneath your car

- Never jack up your car without blocking the wheels

Start by checking the opposite end of the car from the end that is to be raised. If you only have the equipment to chock one wheel, choose the opposite diagonal wheel from the one you will remove. For example, if you raise the front left side of the car, you should choke the rear right wheel.

A wheel was choked using two plastic chocks placed on each side.

Put your gearshift in 1st gear (or in Park if it is an automatic tranny) and then apply the parking brake (emergency brake). Don’t skip to chock the rear wheels just because you have applied the parking brake.

Remove the wheel hub cap, if any, with a small flat-blade screwdriver and loosen the wheel nuts. Remember, just loosen them, not unscrew them.

Place the jack pad under a structure-bearing part of the car (see owner’s manual). Use a jack pad liner (for example wood or rubber) between the jack pad and the car to prevent damaging the car body. Raise the car to such a height you can place a jack stand next to the jack pad (with a jack pad lining between the jack stand and the car). Now lower the car with the jack until all weight is on the jack stand. As a precautionary move, leave the jack raised and let the jack pad have contact with the car body in order to be used as a very last emergency backup if the jack stand should fail.

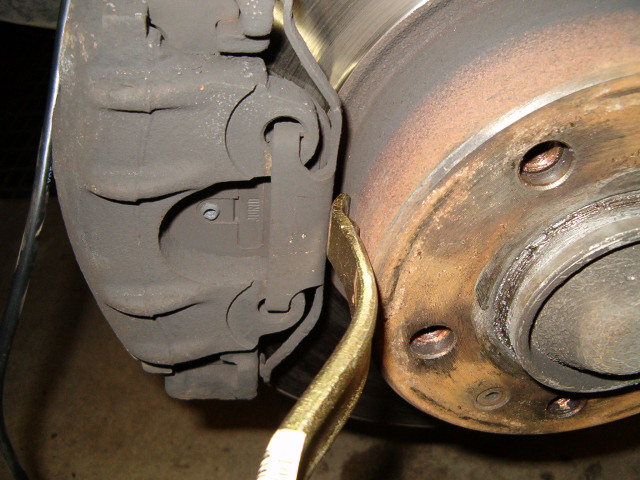

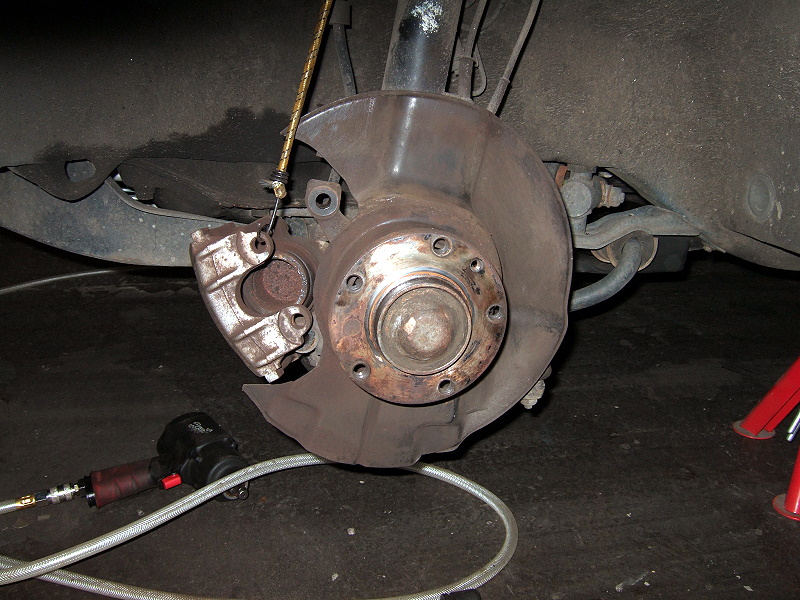

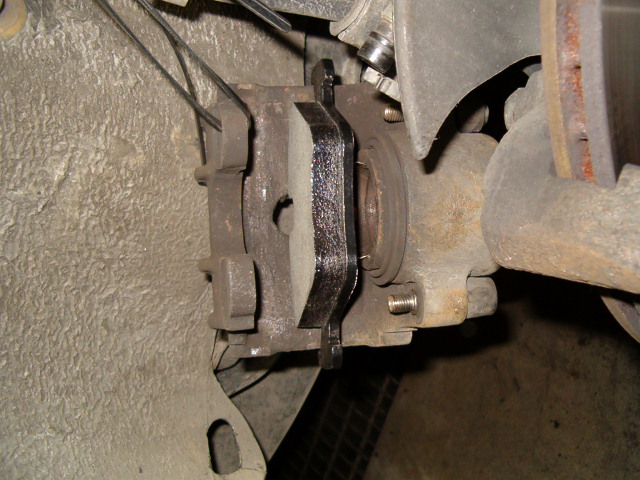

With the car raised, remove the wheel nuts and the wheel. The view in front of you should probably be quite like the one shown in the picture below.

Left front wheel was removed and the brake disc together with the brake caliper is visible.

Removing Brake Caliper And Pads

I would recommend first trying to undo the bolt holding the brake disc (just try to loosen it a turn or so). Although this is not a step included in removing the brake caliper, it is recommended to start with this. Because if there is anything that could go wrong when changing discs and pads, this is the one.

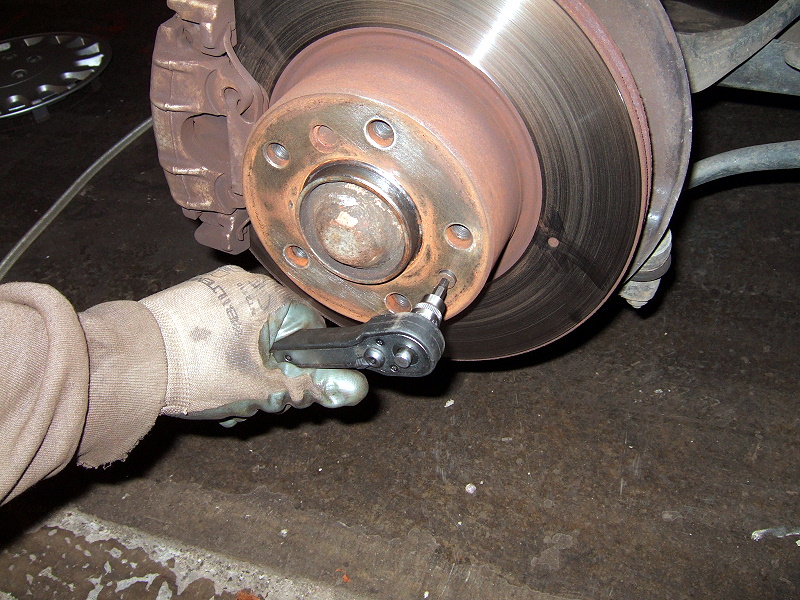

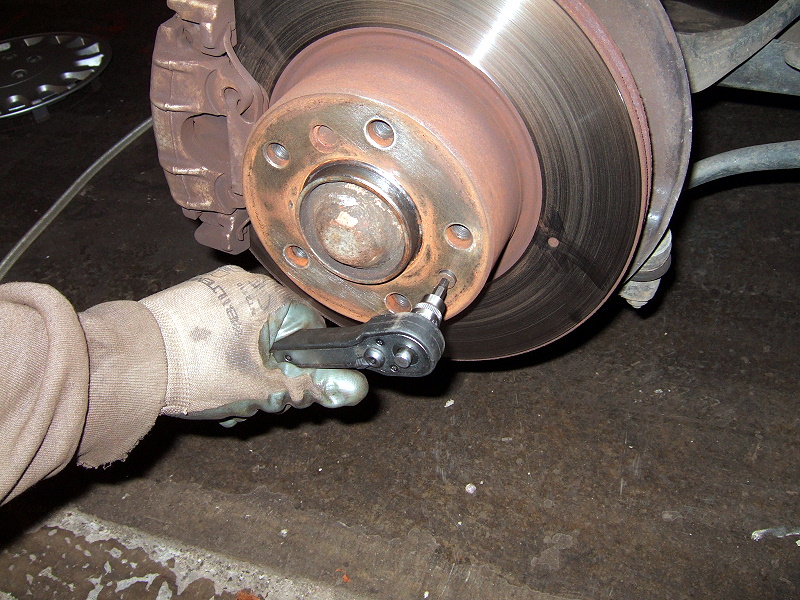

Use a 5 mm Allen key socket on a ratchet and try to undo the screw a turn or so. If you make it round, the easiest thing to do is to drill it out or use an angle grinder and grind away the bolt head (together with the brake disc). But you do have the option to put everything back on and do it another day if you for example have limited time because this will set you back 30-60 minutes or more.

Removing the small (and usually stubborn) bolt holding the brake disc.

If you are working on a wheel with a brake pad wear sensor, start by disconnecting the sensor contact found directly behind the upper part of the brake disc. Simply pull it apart as seen in the pictures below. A brake pad wear sensor can be found on the front left and rear right wheels.

The location of the contact to the brake pad wear sensor behind the brake disc.

The brake pad wear sensor disconnected.

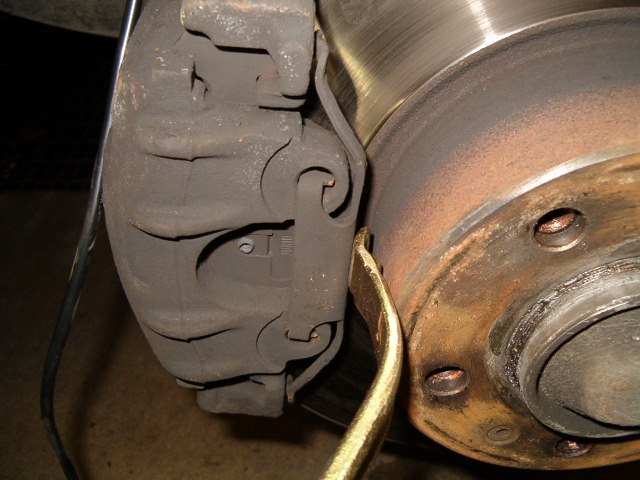

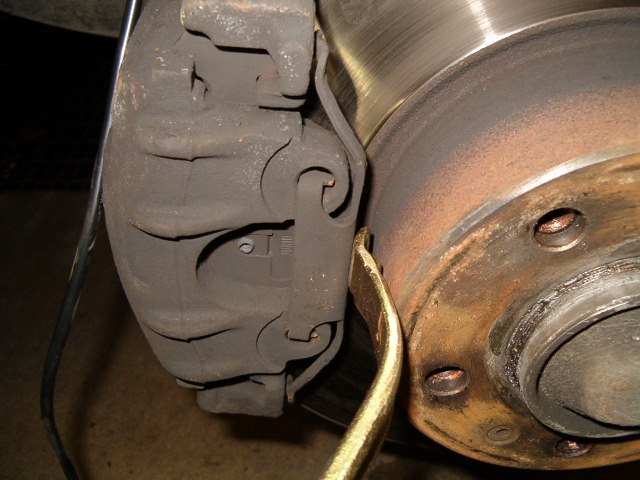

Before the brake caliper can be removed the anti-rattle clip has to be removed first. By using a small tire lever (or a large screwdriver or similar) and bracing against the wheel hub, push the anti-rattle clip away from the wheel hub. The upper and lower “hooks” will come loose and the ant-rattle clip can be removed by hand.

Place the tire lever between the anti-rattle clip and the wheel hub and push the clip away from the wheel hub.

By pushing the clip away from the wheel hib the two “hooks” will be released and the clip can be removed.

Now back to the actual steps needed to remove the brake caliper. Use a small flat-blade screwdriver to pry off the dust caps covering the two guide bolts. The dust caps are located on the backside of the brake caliper, see the picture below. To remove the dust caps, simply pry it loose and pull it straight out.

To the left, the location of the dust caps for the two guiding bolts has been marked out with red circles. To the right an example of how to remove the dust cap.

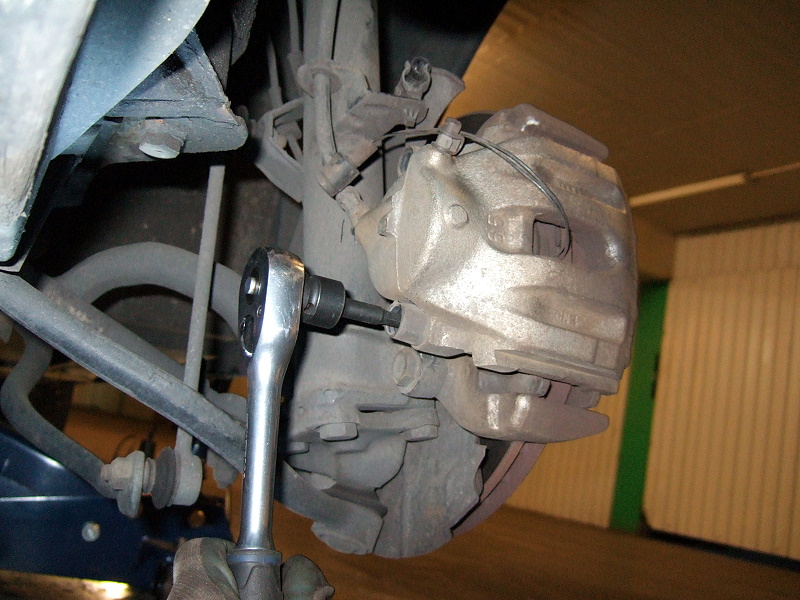

Behind these dust caps the guide bolts are located. Use a 7 mm Allen key to remove them. It is not necessary to remove the guide bolts completely to remove the brake caliper but since you should always inspect and clean the bolts anyway you can remove them directly.

Sometimes they can be hard to get loose but most of the time it shouldn’t be any problem. Recommended is an Allen key socket mounted on a ratchet wrench (a short socket extension bar can also be handy to have). Please note that the 7 mm Allen key is a somewhat odd size and is usually not included when buying an Allen key set.

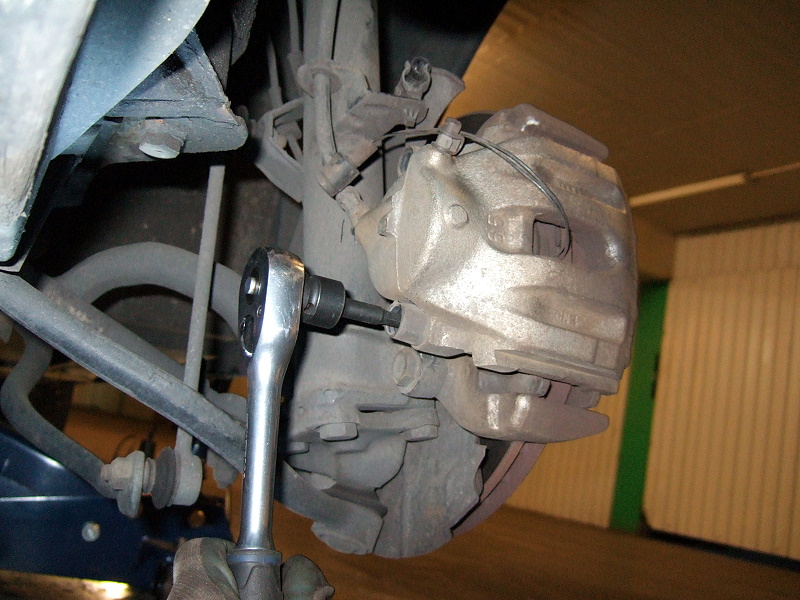

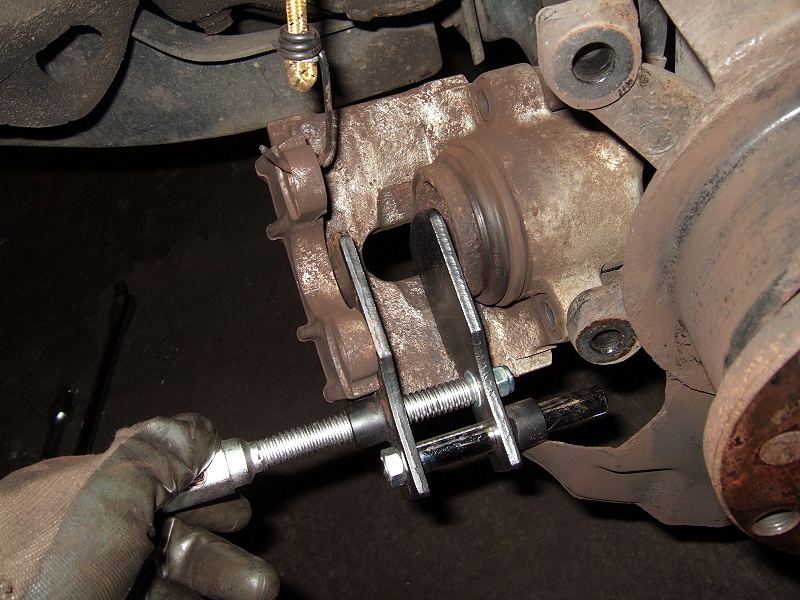

Removing the brake caliper guide bolts with a proper socket and ratchet wrench.

After the guiding bolts have been removed the brake caliper is dismounted simply by pulling it straight out. Use a very small crowbar or large screwdriver if you find the brake caliper doesn’t want to slide right off. Note! Never never let the brake caliper hang from the brake hose! Support it from the chassis with strong wire or similar.

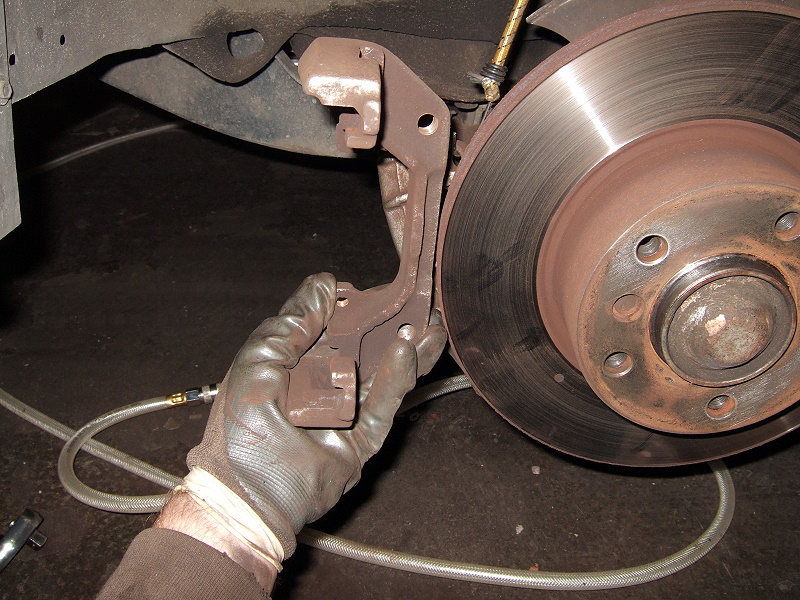

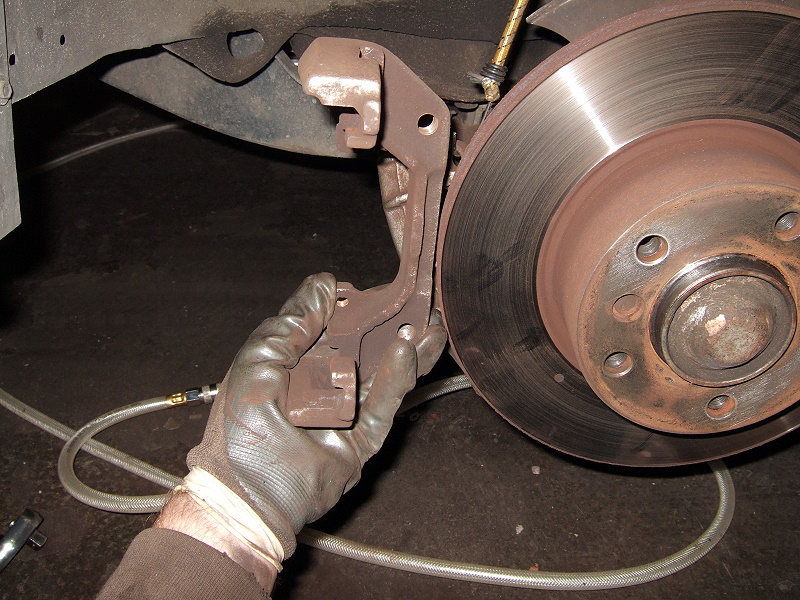

The inner brake pad will come out together with the brake caliper (and the outer brake pad will stay in the brake pad carrier). Remove the inner brake pad and support it with a stiff wire of bungee cord. Finally, remove the outer brake pad from the brake pad carrier.

A very small crowbar or similar can be useful when loosening the brake caliper to be able to pull it right out away from the wheel hub.

Pull the brake caliper straight out (the inner brake pad will follow and the outer brake pad will stay).

Remove the inner brake pad from the brake caliper.

Support the brake caliper with a bungee cord or similar.

Removing Brake Pad Carrier and disc

The brake pad carrier is held into place by two bolts with a 19 mm hex head. Use a long 19 mm socket and a long breaker bar to remove these. They can be quite stubborn so try to find the longest and sturdiest breaker bar you have.

The brake pad carrier was removed.

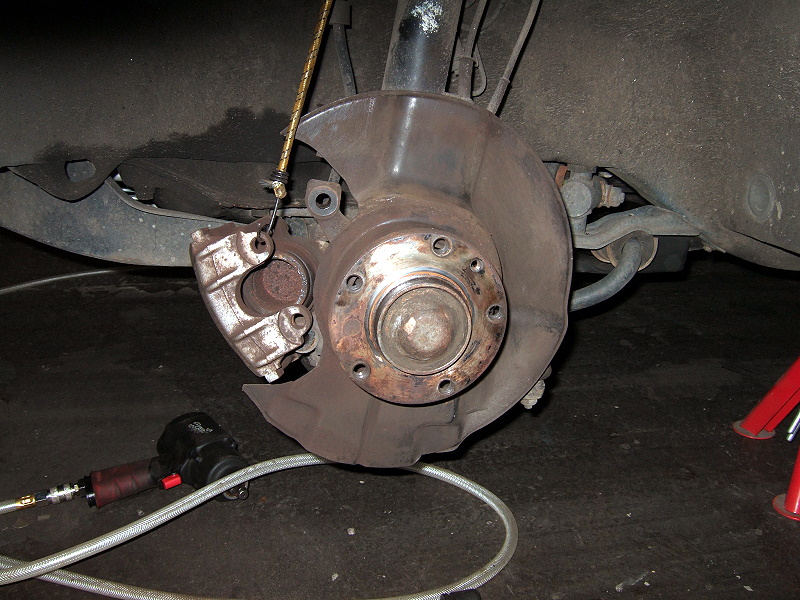

Undo the small bolt holding the brake disc and remove the brake disc. If needed, tap it on the backside with a hammer or similar (use a wooden or rubber hammer if you are planning to reuse the brake disc).

This is how it looks when everything has been removed.

All the removed parts (anti-rattle clip, guide bolts, dust caps, brake pad carrier, brake pad carrier bolts, brake disc bolt, brake pads, and the brake disc).

Cleaning Brake Details

Start by cleaning the guiding bolts. Wipe off grease and dirt and clean the threads using a brass brush. If necessary, use WD-40 and fine-grit sandpaper (like P800 or similar) to remove any rust or hard-to-remove dirt on these guiding bolts. Also, check for straightness (simply roll them over a plane surface and make sure they don’t wobble). Note that the guiding bolts should not be lubricated when it is time to assemble the brake caliper.

Guide bolts to be cleaned.

Clean the brake caliper and the brake disc carrier with the steel brush. Remove as much dirt and dust as possible. Be careful not to damage the sensitive dust seal around the caliper piston mounted in the brake caliper. Take the opportunity to check the dust seal for cracks or damage. Any damage to this dust seal will quickly grow into larger problems such as seized pistons and similar.

Avoid breathing the brake dust since brake friction materials may contain asbestos fibers. (Asbestos is nowadays forbidden in most countries but can be found on some older cars. Already in 1987 Sweden banned sales of new cars equipped with asbestos brakes.)

Clean the hub with fine-grit sandpaper if needed and wipe it clean with CRC Bräkleen and a rag.

Installing Brake Pad Carrier & Disc

Pull out your new brake discs from the box. They are covered with a layer of oil to keep them from rusting, so that has to be removed. Simply clean the brake surfaces (both sides) with Bräkleen and a rag.

New Brembo brake discs are to be unpacked and installed.

Mount the brake disc on the hub and secure it with the small bolt. Put some anti-seize (for example Loctite 8009 which is metal-free high-temperature anti-seize paste) on the threads! And don’t tighten it so damn hard! Hold the brake disc with one hand and fasten the bolt with the other – simply fasten very lightly – it only needs to keep the brake disc from falling off until you mount the tire (this small bolt doesn’t keep the brake disc attached to the wheel hub – it’s the wheel bolts that does that).

Mount the brake pad carrier. Clean the threads on the bolts apply a thin layer of Loctite 8009 (or similar anti-seize paste) and torque them down with 110 Nm.

The brake pad carrier torqued down.

Installing Brake Caliper & Pads

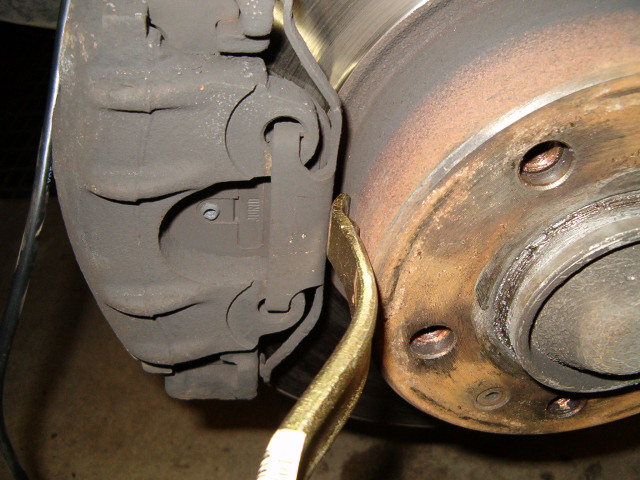

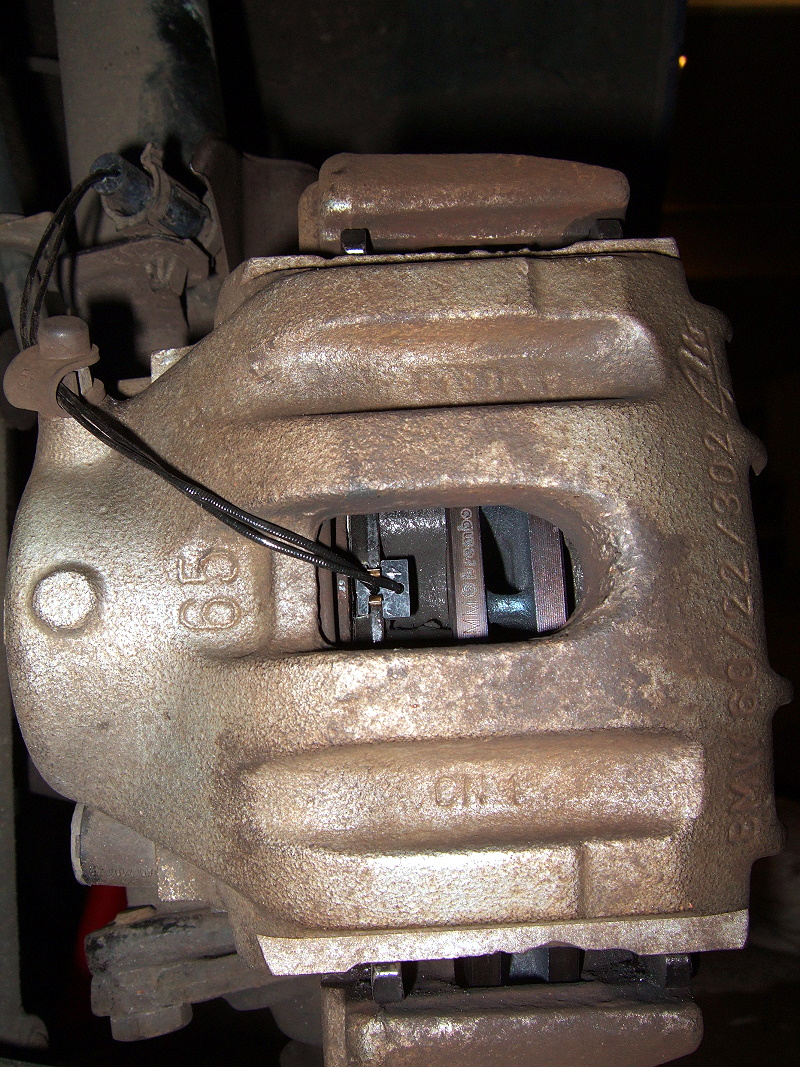

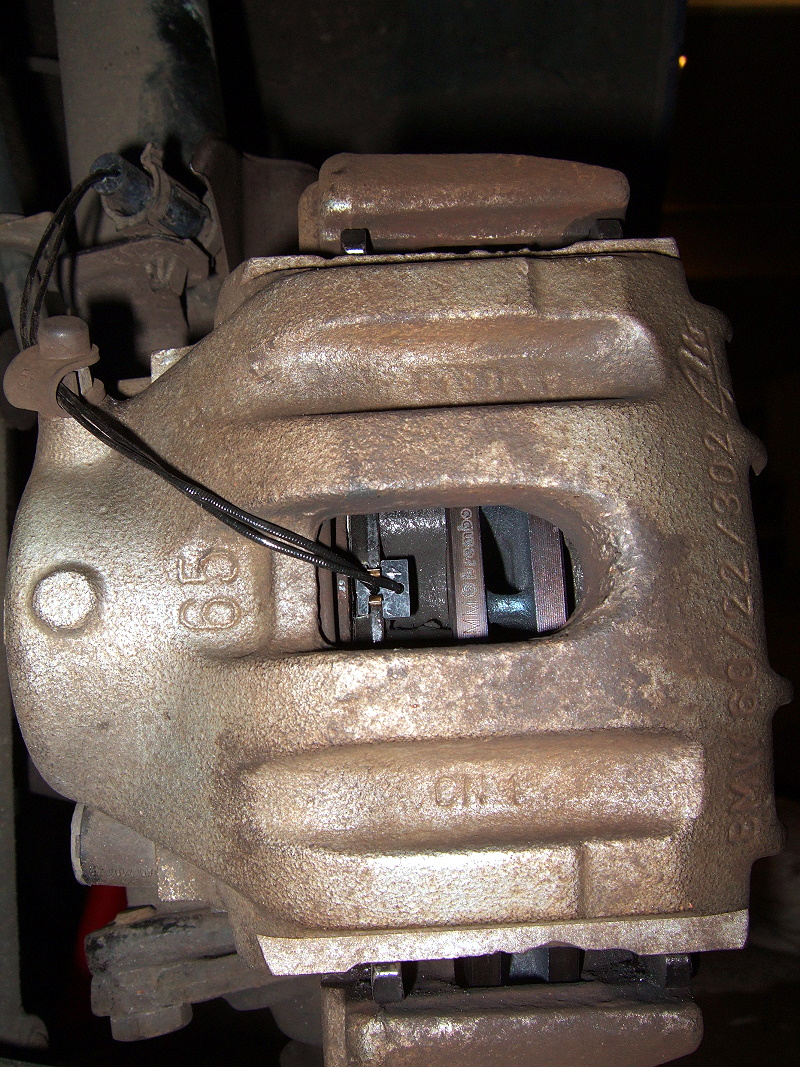

Since the new brake disc and brake pads are a lot thicker you must push back the piston, otherwise you will never be able to slide the brake caliper back in place. You can use a brake pad spreader or a large polygrip (but be careful not to damage the dust seal around the piston if you use the polygrip).

NOTE! Before you start pushing back the piston, take a look at the level of the brake fluid reservoir. If it’s close to full you need to remove some using a syringe or similar. Because when you push back the piston the level of brake fluid will rise and eventually flow over (and brake fluid is very aggressive to paint so you really don’t want to have brake fluid all over the place).

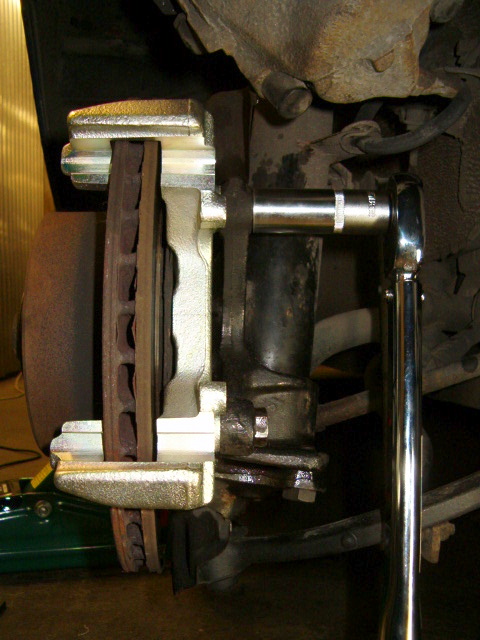

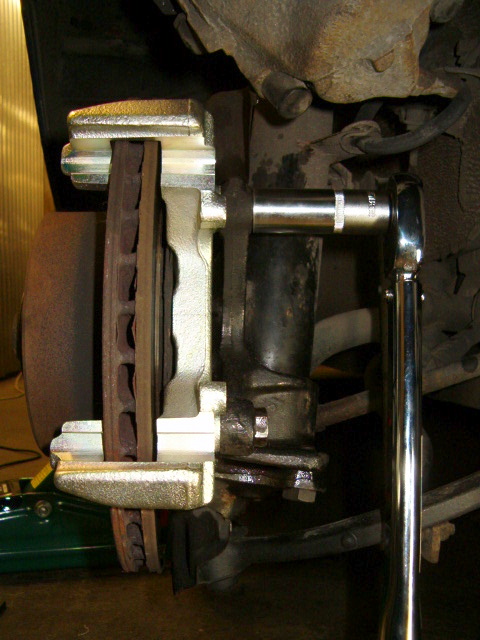

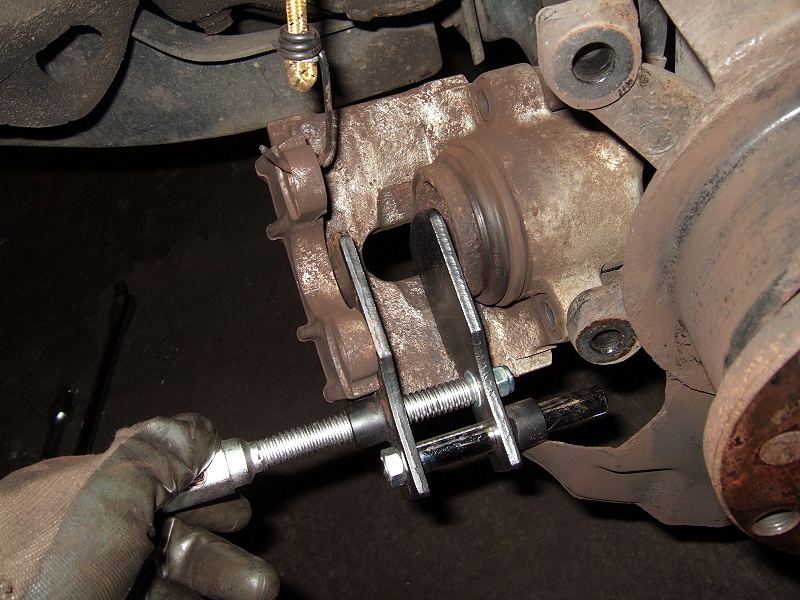

Press back the caliper piston into the brake caliper (to make room for the thicker brake pads) by using a disc brake pad spreader.

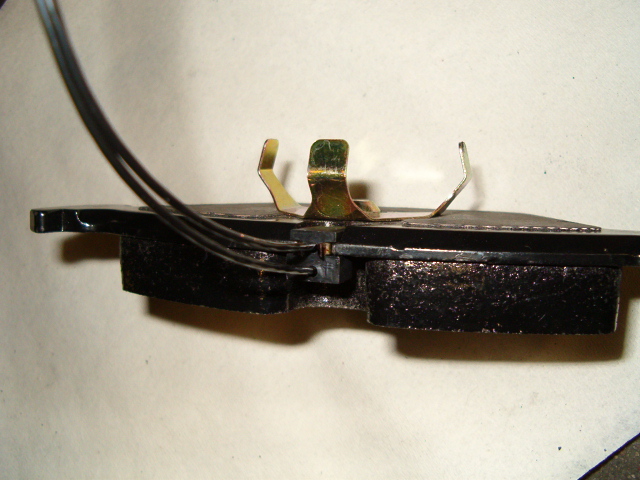

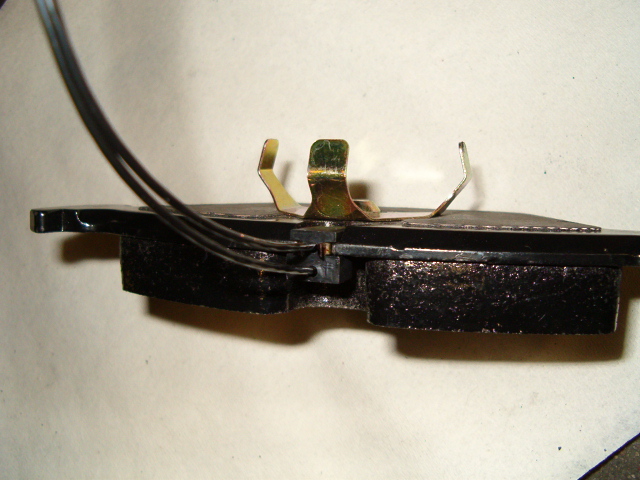

If the wheel you are replacing brake pads on is equipped with a brake pad wear sensor, insert the new sensor into the cutout in the new brake pad as shown in the picture below. The brake pad with the metal spring on the back shall always have the brake pad wear sensor.

The brake pad wear sensor is mounted into the brake pad (always mounted on the brake pad with the metal springs on the back i.e. the one closest to the caliper piston).

Smear a small amount of Loctite 8009 (or similar anti-seize) at the contact areas between the brake pads and the brake pad carrier to ensure smoother movement of these components. Do not apply any anti-seize on the brake disc surface or brake pad lining! If it should happen just remove it directly with CRC Bräkleen or similar.

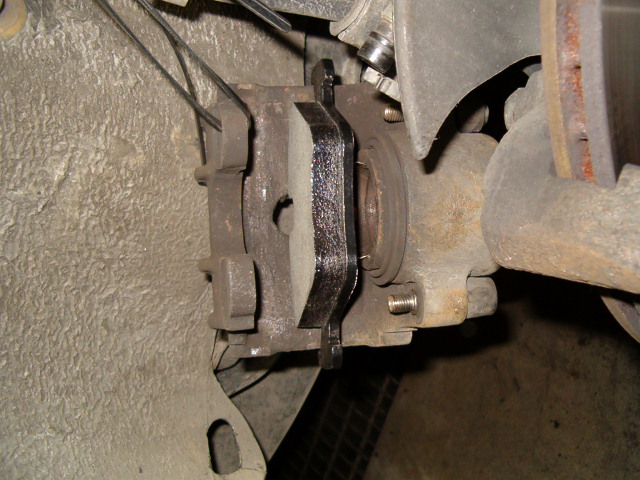

Place the outer brake pad in the brake pad carrier and the inner brake pad in the brake caliper with the metal springs into the hole of the caliper piston, see picture below. Route the brake pad wear sensor contact through the hole of the brake caliper and carefully slide the brake caliper in place on the brake pad carrier (as you did when you removed the brake caliper but in reverse).

Place the outer brake pad in the brake pad carrier (flush with the brake disc)…

Then place the inner brake pad (with the metal springs into the hole of the caliper piston) into the brake caliper.

Put back the guide bolts and tighten them down to 35 Nm. Put the dust caps back on. Reconnect the brake pad wear sensor. It is highly recommended to guide the wire for the sensor through the dust cap of the bleeder bolt, otherwise, it is very likely the rim will scuff against the wire and after a while, the wire is cut off. Finally put back the anti-rattle clip.

Correctly located brake pad wear sensor wire.

Put the wheel back on and do the wheel bolts hand tight, remove the jack stand and slowly lower the car until the wheel slightly touches the ground (enough to keep it still while you tighten the wheel bols). Tighten the wheel bolts their final torque, usally around 100 Nm. Lower the car completely and remove the wheel chocks.

NOTE! Depress the brake pedal several times BEFORE you use your car, this to ensure the piston and brake pads are located correctly – which is tightly against the brake disc.

Tightening Torques

| Brake caliper to brake pad carrier (guide bolt) | 35 Nm (26 ft-lb) | |

| Road wheel to hub | 100±10 Nm (74±7 ft-lb) |

Thickness Specifications

The minimum thickness specifications for front and rear brake discs are listed below. The source for all values are BMW TIS [2]. If any hesitations what is valid for your car, the minimum allowable thickness is stamped on the wheel hub for all original equipment brake discs.

| Brake disc min. thickness – front (not valid for solid, 4WD, 540i and M5) | 20.4 mm | |

| Brake disc min. thickness – rear (not valid for 540i and M5) | 8.4 mm |